PIPE PLANNING. HOW WE DO IT?

With advanced software, algorithms and formulas W5 Spool Tracker removes human error from the equation

On completion of the tender, we are confident that we can answer the question WHO, WHAT, WHEN, WHERE & WITH WHAT With this answered, we KNOW our tender is correct and open to scrutiny. Thus completing the pipe planning process with complete accuracy.

STEP 1

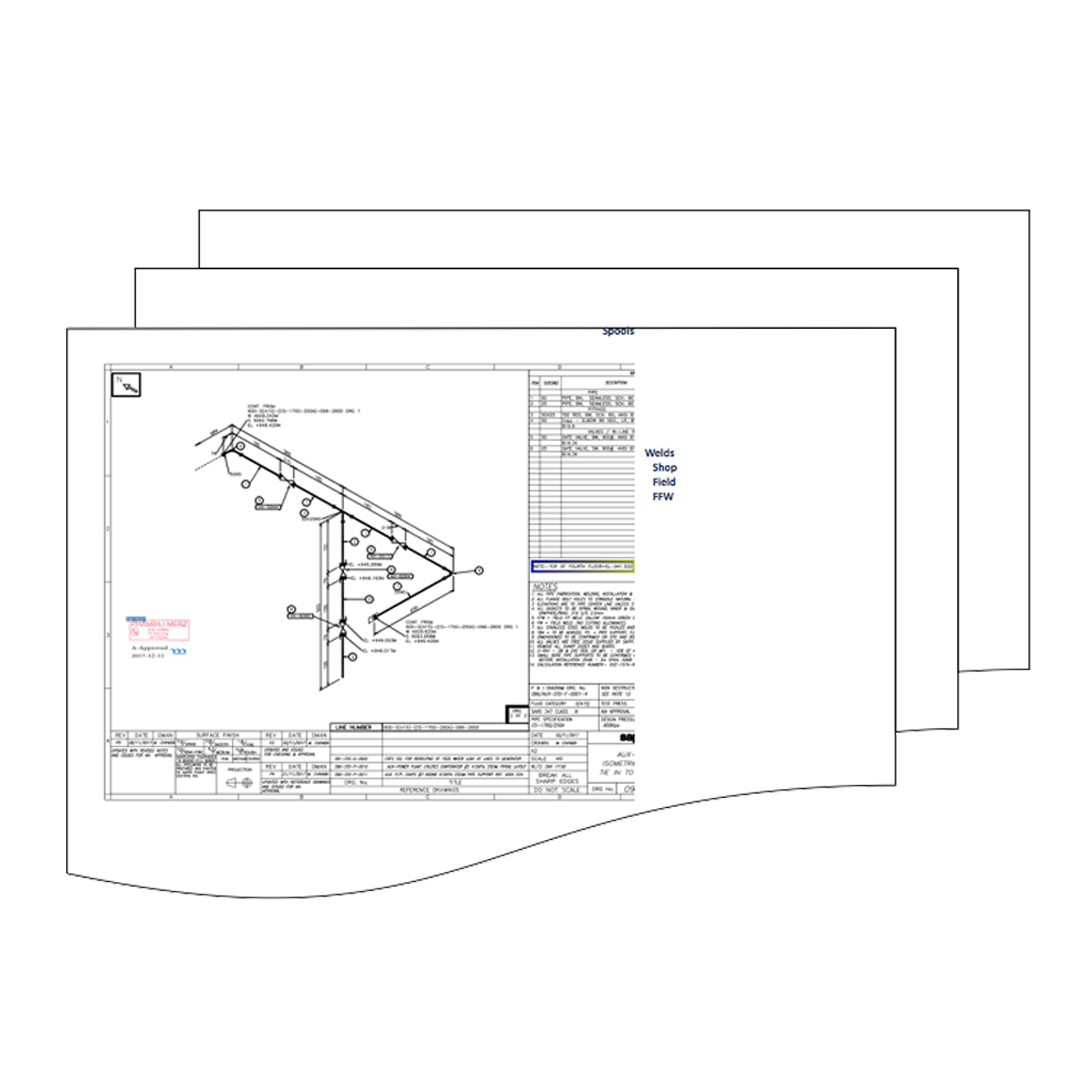

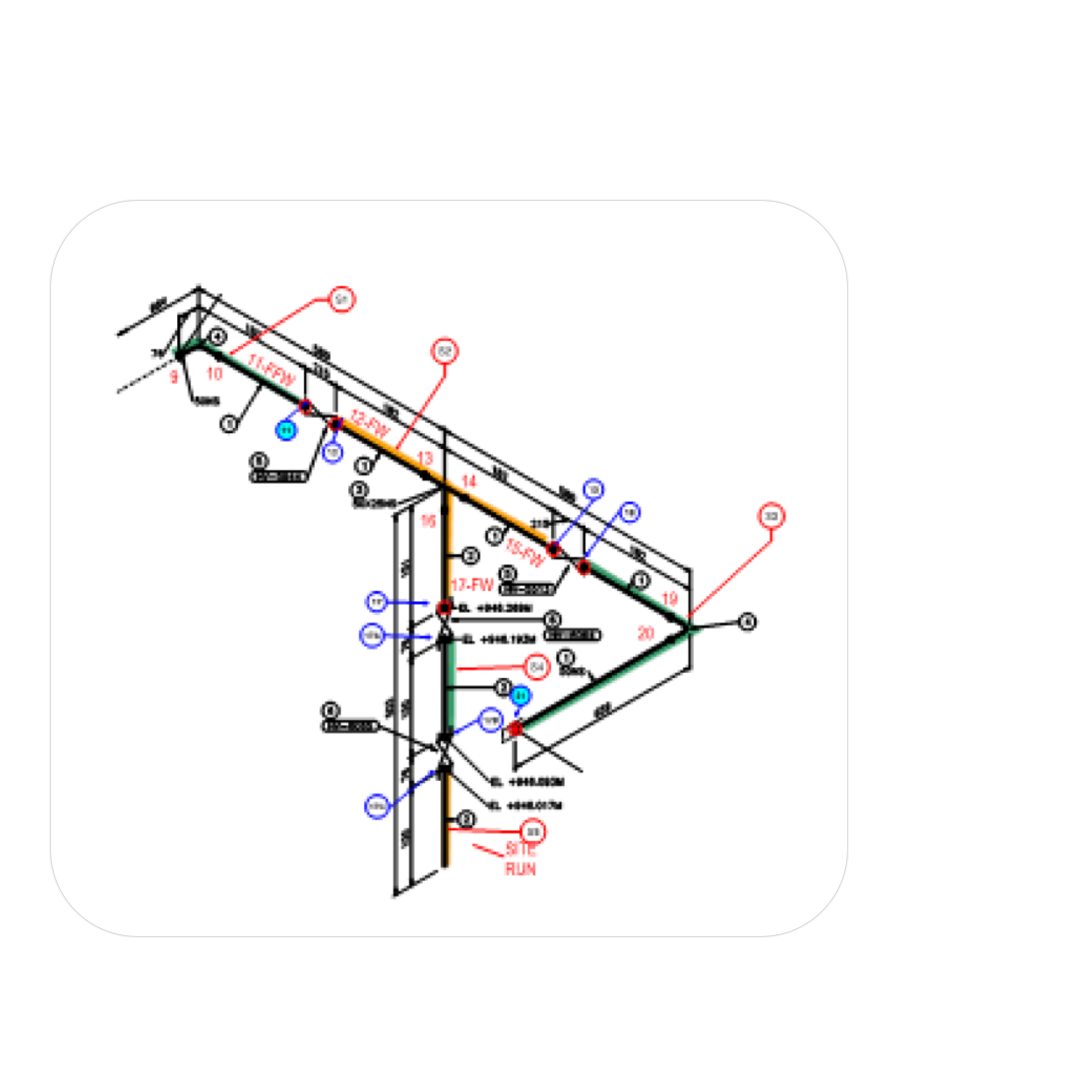

We take your standard ISO drawing and break it down, colour code it and segment the different spools

We segment the ISO drawing into spools, welds, shop, field & FFW. We colour code the different pipe lengths and change colour at each weld

Segmenting and colour coding the ISO Drawings as above, helps us easily highlight and pull the relevant information which we then input into W5 Spool Tracker

STEP 2

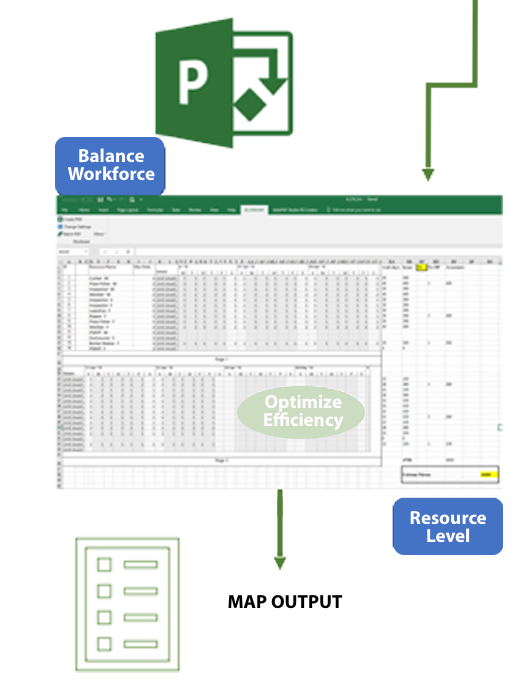

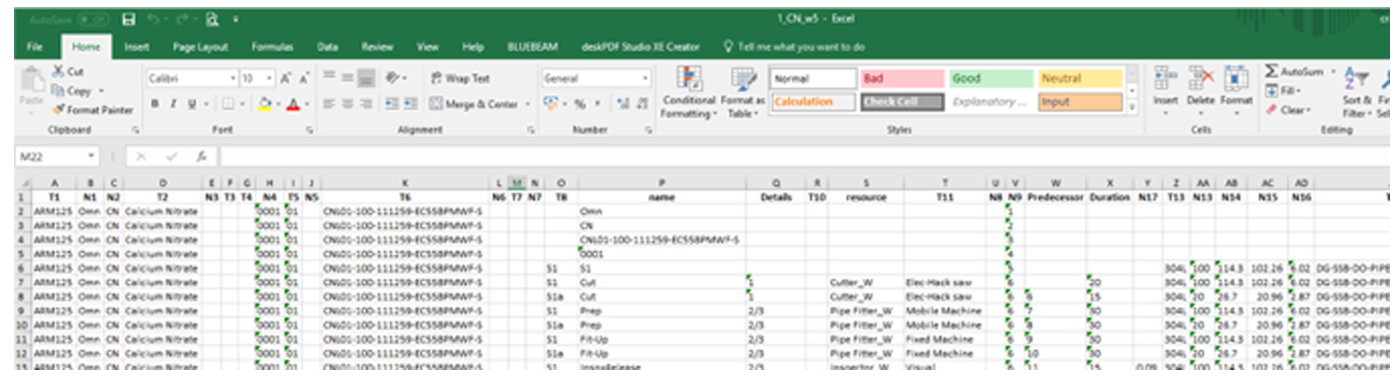

Once W5 Spool Tracking Software has processed the newly categorised data, it then outputs a highly accurate generated report that is uplifted by planning Software. All the information required for the planning of the project is processed by W5 Spool Tracker.

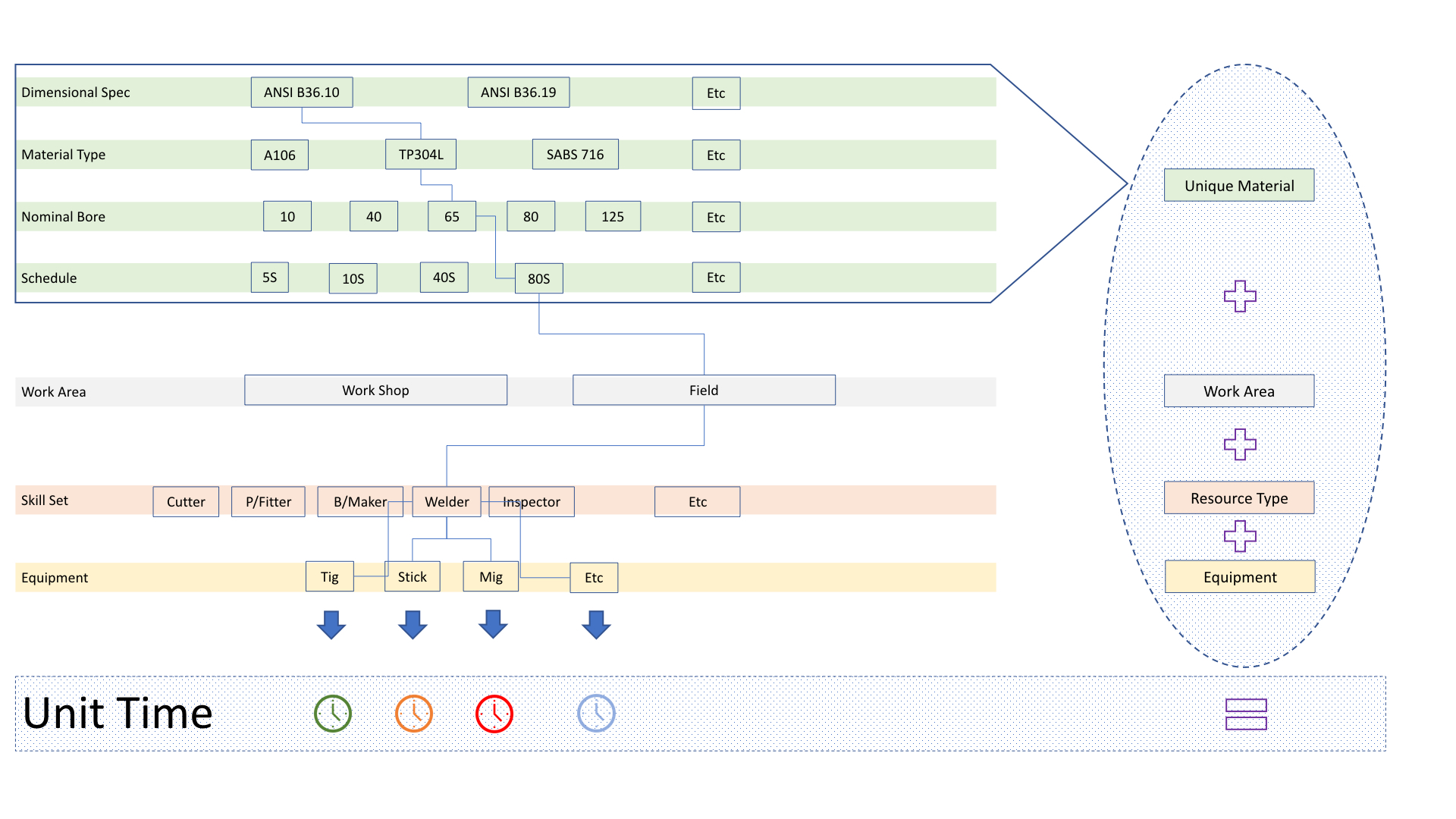

It has an advanced library and considers the variables below

Materials: Type Nominal Bore, O.d., I.d , Wall Thickness , Kg’s per meter

Welders: Name, stamp #, qualifications

Equipment: Available tools per function (eg “Cutter” hacksaw, bandsaw, cut-off saw…)

Pre-Planners: Name, contact, availability details (report on all captured Drawings, spools etc per individual)

Time: Per material type, diameter, wall thickness, location, equipment used etc

W5 takes all the mentioned variables and allocates it to

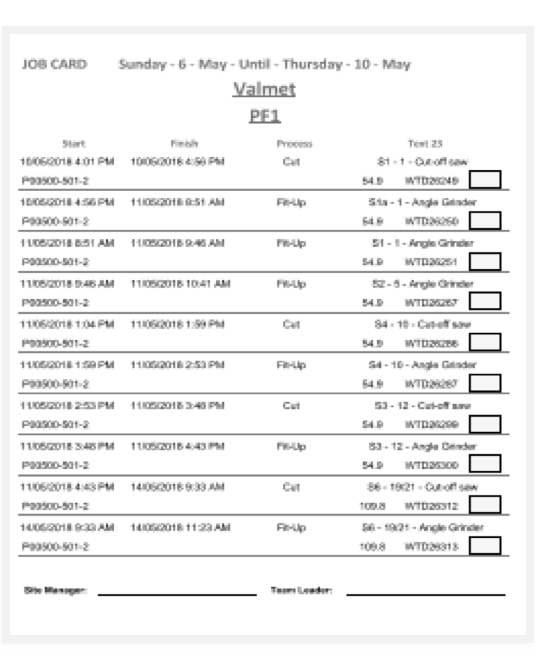

WHO, WHAT, WHEN, WHERE AND WITH WHAT

Who will be doing the job?

What task will they be doing?

When will they be doing the job?

Where will they be working?

With what tools?

STEP 5 & 6

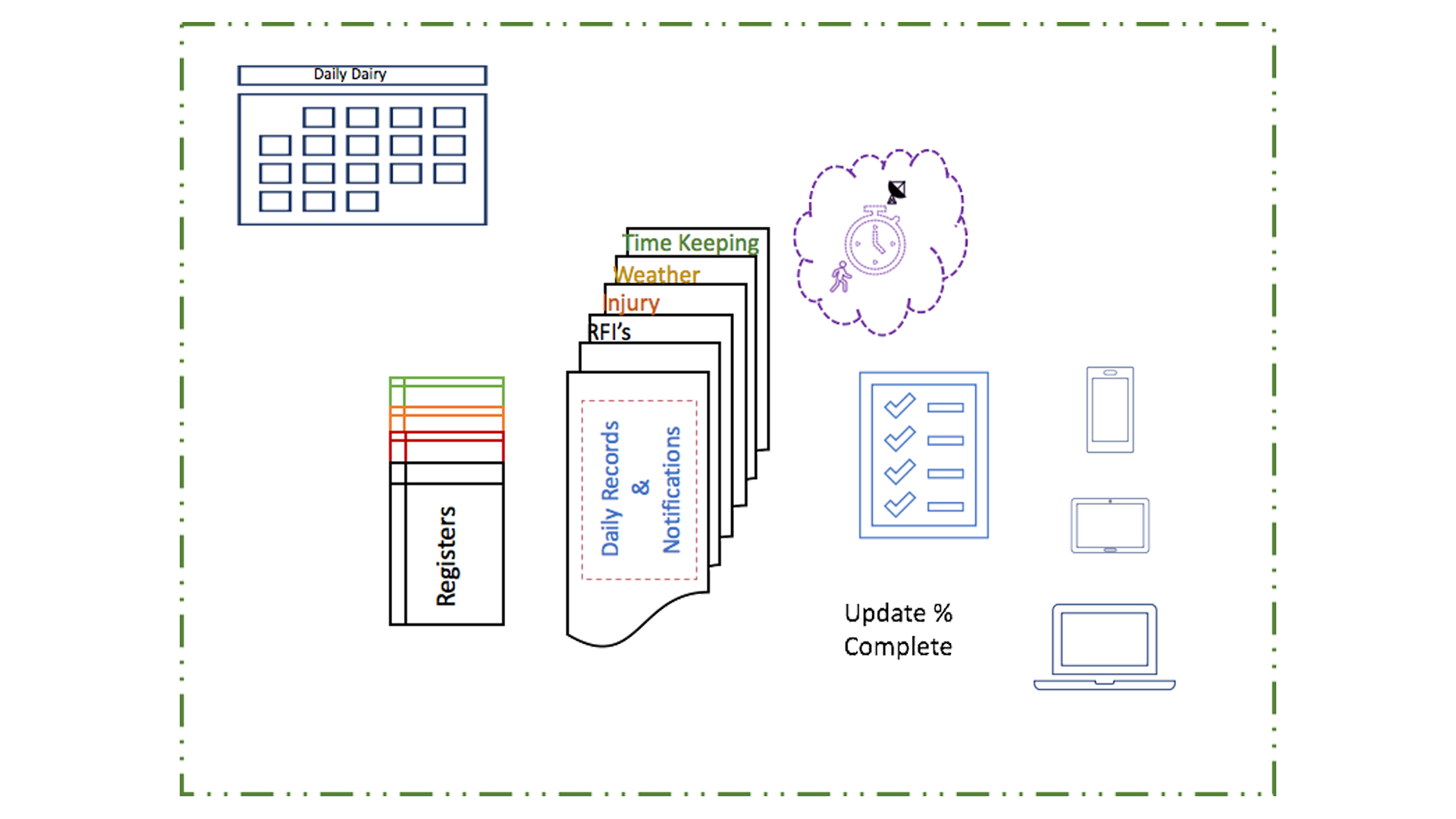

Even after the planning phase has finished and the construction of the job has started, we can still input information based on unpredictable factors such as weather changes, timekeeping issues, injuries, and RFI’s. W5 will update the plan and reports to factor in the new information to make up for lost time so that the construction process can continue as normal.

We take a time value for a specific material associated with a relevant working area that makes use of a professional resource and using a company-specific tool

PHONE

WORK

HOME